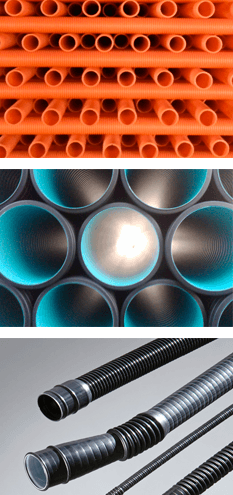

Corrugated Pipes

TECHNOLOGY

The concept of corrugator can be considered as the basis of Itib origin. This is why Itib has been a European main character in the development and marketing of producing lines. Thanks to years of experience in the field of machines, today Itib is considered as one of the most innovative and reliable corrugated plastic pipes producers in Europe.

Itib claims a close cooperation with the main raw materials producers; this is the reason for which it is possible to propose items produced in base polymers and technopolymers with high mechanical and thermic performances.

The range of pipes produced is wide: with standard geometry, pipes produced with ITIB own tools, as well as pipes designed directly on customers’ drawings. We have at our disposal several applications in:

- HDPE

- PP, modified PP, self-extinguishing PP

- PA6, toughened PA6

- 12

- TPE-V

- TPE-E

Itib pays great attention to market evolution and answers to demand in increasing thermic-mechanics performances through experimentation and setting up of new materials, as well as cooperation in the development of the same together with producers.

The corrugators are equipped with the most modern process controls, talking of the treatment of raw materials by dehumidifier or gravimetric dosing system as well as speed setting and extrusion temperatures.

Corrugators work with pressured air inside the pipe or with vacuum moulds for a perfect forming of the pipe even in case of important differences in the diameter.

Itib can count on a skilled staff trained and aware of critical aspects of production process.

The corrugated pipe can be supplied in coils or can be cut at a defined measure by precision devices and technologies that guarantee repeatability and cleaning.

The absence of holes and imperfections is ensured by electromagnetic or optical detection systems.

Air leakage test can be implemented in case of need both on the pipe and on the complete system with assembled components.